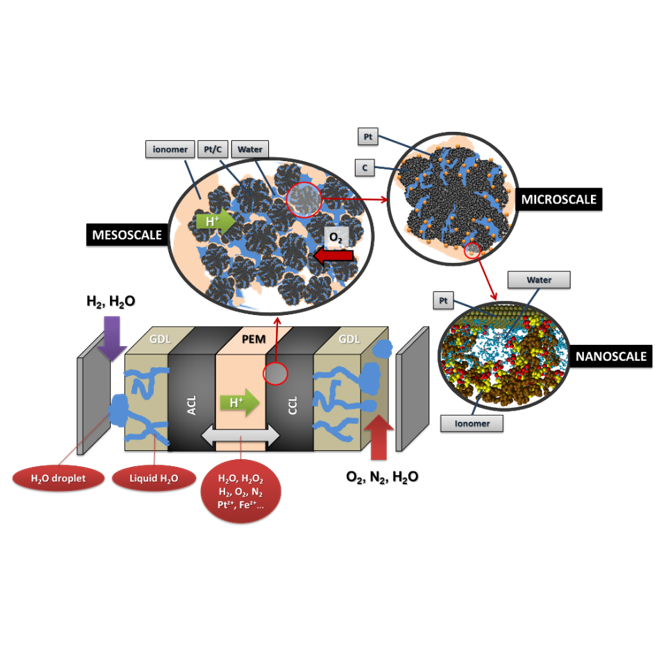

We develop multiscale computational models to simulate the operation principles of electrochemical energy materials, interfaces, components and full devices (batteries, fuel cells, electrolyzers...) as well as their manufacturing. Such multiscale models decribe mechanisms along different spatio-temporal scales. Their goal is to provide interpretation of experimental data, to optimize electrochemical energy devices and to provide advanced design guidelines. Examples of multiscale modeling approaches developed by the team include: using Coarse Grained Molecular Dynamics to predict 3D-resolved electrode mesostructures from their manufacturing simulation, which are then used in electrochemical energy device performance simulators (sequential coupling); using kinetic Monte Carlo (kMC) models resolving interfacial electrochemical kinetics from species concentrations resolved with continuum models describing these species transport in a porous electrode (iterative coupling); using continuum models describing electrochemical reactions and transport mechanisms with temperature-dependent parameters at the porous electrode scale coupled with a continuum model describing thermal management in the cell scale (tight coupling). We develop also hybrid models coupling data-driven models (supported on Artificial Intelligence) and physical models. We carry out advanced experimentations to extract parameters to feed into the models, to validate them and to follow the guidelines proposed by the models: this includes manufacturing battery electrodes, assembling cells and characterizing their textural and electrochemical properties. For performing these experimental activities, we benefit from the free access to the Laboratoire de Réactivité et Chimie des Solides facilities, including the battery manufacturing pilot line of the French Network on Electrochemical Energy Storage (RS2E).

RESEARCH ACTIVITIES

Prof. Franco's team research focuses on electrochemical energy devices, through an inter-disciplinary approach crosscutting physical electrochemistry, materials science, multiscale modeling, data science, artificial intelligence and virtual/mixed reality.

1/2. Advanced Tools for Design and Optimization of Electrochemical Energy Devices

Multiscale Computational Modeling and Advanced Characterization

Data Science and Artificial Intelligence

We develop and use data mining algorithms to automatically extract data from experiment and modeling-based databases. We develop and use Natural Language Processing text mining algorithms to automatically extract battery data from scientific publications.

We also develop and use Artificial Intelligence/Machine Learning (e.g. Support Vector Machines, SISSO, Deep Neural Networks, etc.) pipelines to ease the parameterization of physical models and to discover the interdependencies between experimental parameters (e.g. impact of manufacturing parameters on final properties of a lithium ion battery electrode). We use these pipelines for both classification and regression purposes: these algorithms have the capabilities of automatically finding patterns in big data, reveal hidden information and to find solutions to complex problems. We use them in combination with optimization algorithms (e.g. Bayesian Optimization) to predict the best recipes for materials and interfaces synthesis, for electrode manufacturing and cell operation. They provide also a powerful engineering tool for inverse design given targets in terms of performance, cost, safety, etc. for electrochemical energy devices. We also use Deep Learning to train surrogate models that mimic the time-series produced by physics-based models and the real systems under our investigations.

Virtual Reality and Mixed Reality

We develop innovative serious games and digital twins using Virtual Reality (VR) technology to teach electrochemical energy devices (e.g. battery) concepts at the University (from undergraduate to doctorate levels), to gigafactory operators, and also to the general public in the context of Science festivals and other events. These serious games allow interacting with battery materials, electrodes, cells and their manufacturing process in an immersive way. They also allow experiencing impossible situations in real life, such as flying inside battery composite electrodes to calculate their geometrical tortuosities at the micrometer scale or experiencing the electrochemical behavior of different battery types by driving an electric vehicle. Such serious games embed mathematical models with different levels of complexity representing the physical processes at different scales. We also develop and use VR and Mixed Reality tools to support electrochemical energy devices R&D activities by scientists and engineers: e.g. immersive and interactive visualization of electrode mesostructures arising from tomography characterizations or computational models, and decision-making assistance in the battery manufacturing process. We also develop Mixed Reality simulators (e.g. Smart Power Grid) mixing VR environment with interactive real objects, to teach students how to manage the complex balance between electricity production, distribution, storage and consumption.

2/2. Applications to Electrochemical Energy Storage and Conversion

Lithium Ion, Sodium Ion & Solid State Batteries: Manufacturing & Performance

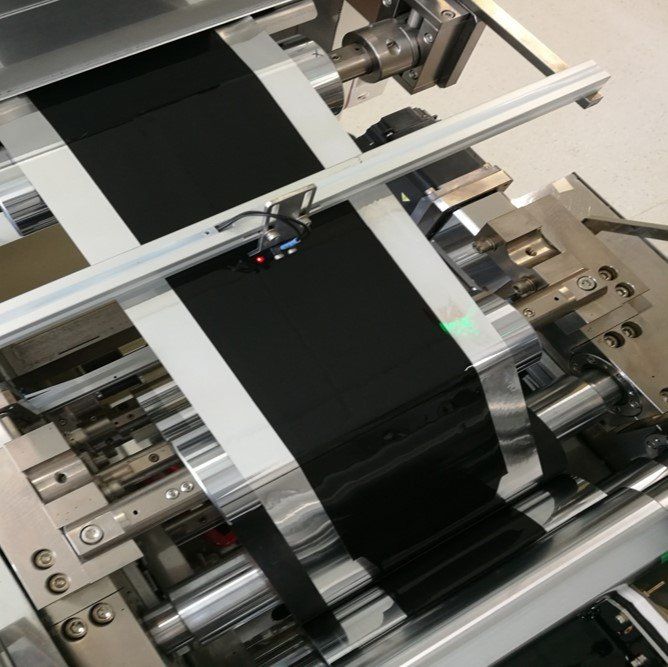

We investigate the impact of electrode mesostructure on the performance and aging of Lithium Ion Batteries (LIBs). Our approach encompasses 4D-resolved models (i.e. 3D space + time), structural and in house electrochemical experimental characterizations. We also have a strong activity about the development and demonstration of a predictive multiscale computational platform (digital twin) of the wet manufacturing process of LIBs initiated in Prof. Franco's ERC Project "ARTISTIC". The latter pioneering initiative, encompasses multiple simulation techniques such as Coarse Grained Molecular Dynamics and Discrete Element Method (LAMMPS/LIGGHTTS) to simulate electrode slurries, their mixing, drying and calendering, Lattice Boltzmann Method (C++) to simulate electrolyte filling and continuum 4D-resolved models (for example coded in Comsol Multiphysics) to simulate the electrochemical performance of the resulting electrodes and cells. Furthermore, Artificial Intelligence/Machine Learning (AI/ML) is used by us to speed up the parameterization of physical models and to unravel experimental parameters interdepedencies. We also use AI/ML to derive surrogate models that we embed into optimization algorithms (e.g. Bayesian Optimizers) for performing inverse design (e.g. predicting which manufacturing parameters values to adopt in order to reach a desired battery cell performance target) and to predict cells lifetime. We also work in the extension of these tools for the optimization of the manufacturing of Sodium Ion and Solid State Battery cells, as well as for dry processing methods (e.g. extrusion). Like other research activities in our group, this one benefits from our free on-site access to the RS2E (French Network on Electrochemical Energy Storage) battery manufacturing pilot line. We use this pilot line to produce the experimental data needed for calibrating, training, and validating our models.

Lithium Sulfur Batteries

We investigate electrochemical reactions and transport processes in Lithium Sulfur Batteries (LSBs). We are in particular interested on the impact of the cathode mesostructure (initial porosity, specific surface area, sulfur loading, sulfur localization, etc.) and electrolyte volume on the performance and aging of LSBs. We also investigate how to reduce polysulfides crossover through separators and the associated shuttle effect. We have also studied the operation principles of Quasi Solid State LSBs. Our approach encompasses continuum models (Matlab, Comsol Multiphysics, etc.) describing the interplays between transport processes and electrochemical reactions leading to the formation of polysulfides, 4D-resolved kinetic Monte Carlo models (in house code "MESSI" coded in Python) able to predict the spatial location of the reaction products upon discharge depending on the operation conditions, and in house advanced experimental characterizations. Our physical models simulate discharge and charge operation of electrolyte/carbon electrode interfaces, of electrodes and of full cells. They are also able to simulate electroanalytical experiments (e.g. Cyclic Voltammetry) aiming at unraveling the influence of the electrolyte composition on the reaction mechanisms involving polysulfides.

Metal Air Batteries

We investigate electrochemical and transport mechanisms in Lithium Air Batteries. This includes lithium peroxide nucleation phenomena, lithium peroxide decomposition during charge and electrolyte degradation mechanisms. We are also particularly interested on the impact of the cathode electrode mesostructure on the reproducibility, discharge performance and rechargeability of the cells. Our approach encompasses continuum modeling (Matlab) to investigate reaction mechanisms and to propose guidelines for optimized electrode architectures, kinetic Monte Carlo models (Python) to investigate the impact of pores morphology and electrode surface chemistry on the lithium peroxide formation mechanisms, Pore Network Models (C++) to assess the impact of the cathode anisotropy on the formation of lithium peroxide and oxygen transport properties, and in house electrochemistry experiments. These activties have been also carried out in link to Nuclear Magnetic Resonance (NMR) spectroscopy experiments carried out in collaboration with Prof. Clare Grey's group in University of Cambridge, UK. We are very much interested in extending these modeling and characterization approaches to other types of Metal Air Batteries such as Zinc Air Batteries.

Redox Flow Batteries

We study Semi-Solid Redox Flow Batteries (SSRFBs) containing particles suspensions and Redox Flow Batteries (RFBs) with organic active molecules. In the case of SSRFBs we are interested on the interplay between fluid dynamics, particle suspensions dynamics and electrochemistry. We have studied in particular Silicon-based semi-solid electrodes for SSRFBs. Regarding organic-based RFBs, we study the electrochemical and aging mechanisms upon discharge and charge with multiple types of active molecule chemistries. We also investigate electrochemical double layer effects on the reactivity. Our approach encompasses 4D-resolved kinetic Monte Carlo for the simulation of REDOX reactions, aging mechanisms and particle suspensions dynamics, Dissipative Particle Dynamics for investigating particle suspension dynamics, and Discrete Element Method coupled to continuum modeling for the prediction of electrochemical performance. Our activities are carried out in strong link with in house experimental characterizations.

Polymer Electrolyte Membrane Fuel Cells and Electrolyzers

We investigate electrochemical mechanisms, aging and contamination phenomena in Polymer Electrolyte Membrane Fuel Cells and Electrolyzers. Particular focus of our studies is on electrocatalysis, catalyst/support/ionomer degradation processes and synergies between contamination reactions. We are also interested on the dynamical behavior of interfaces between catalysts and ionomer (electrochemical double layer effects), and on the electrodes mesostructure impact on the performance and aging of these devices. Our approach encompasses Coarse Grained Molecular Dynamics (LAMMPS/GROMACS) for the prediction of the electrodes microstructures (as a function of their manufacturing parameters) and of the membrane microstructure (as a function of its hydration and aging state), 3D-resolved kinetic Monte Carlo (Python) for the investigation of Oxygen Reduction and other reactions and N x 1D-based continuum modeling (Python, Matlab) to assess the interplay between electrochemistry and transport mechanisms. Models results are confronted with experimental results arising from experiments carried out by external collaborators.